HISTORICAL WINDOWS

DO YOU HAVE ANY QUESTIONS?

WE WILL BE IN CONTACT WITHIN THE NEXT WORKING DAYS.

"*" indicates required fields

DO YOU HAVE ANY QUESTIONS?

WE WILL BE IN CONTACT WITHIN THE NEXT WORKING DAYS.

"*" indicates required fields

Historical windows are mostly produced when restoring historical buildings, to maintain authentic, pristine look but at the same time add modern functionality. The original design of these windows will stay the same as the craftsman wanted decades ago but they will be more convenient, ergonomic and with better thermal and sound insulation than the original. We offer the following kinds of historical windows:

HISTORIC-TYPE WINDOW EV47/EV47

HISTORIC-TYPE WINDOW EV47/IV78-3

HISTORIC-TYPE WINDOW EV47/IV78-23

HISTORIC-TYPE WINDOW (CHAMFERED) EV47/EV47

COUPLED WINDOW EV31/IV68

Historical window non-standard solutions

Taking into account that every wooden window order is unique, Flora adapts to solving different needs in every case. The produced historical windows can be different shapes and sizes – windows can be rectangle, triangle, square or other shapes. They can be openable or not. Our offered solutions can be historic-type or chamfered but if needed we can produce coupled window solutions. You can ascertain our versatile and professional experience by seeing our finished jobs in the gallery.

Matching fittings and finishes

We offer safe historical window production solutions and hinge systems in wide array, combining decorative elements and window original design with modern technologies improving thermal efficiency, durability and security of the windows. The wide choice of fittings and finishes allows matching these windows with different kinds of architecture as well as produce them as close to original as possible. Additionally despite their historical appearance the windows meet modern requirements.

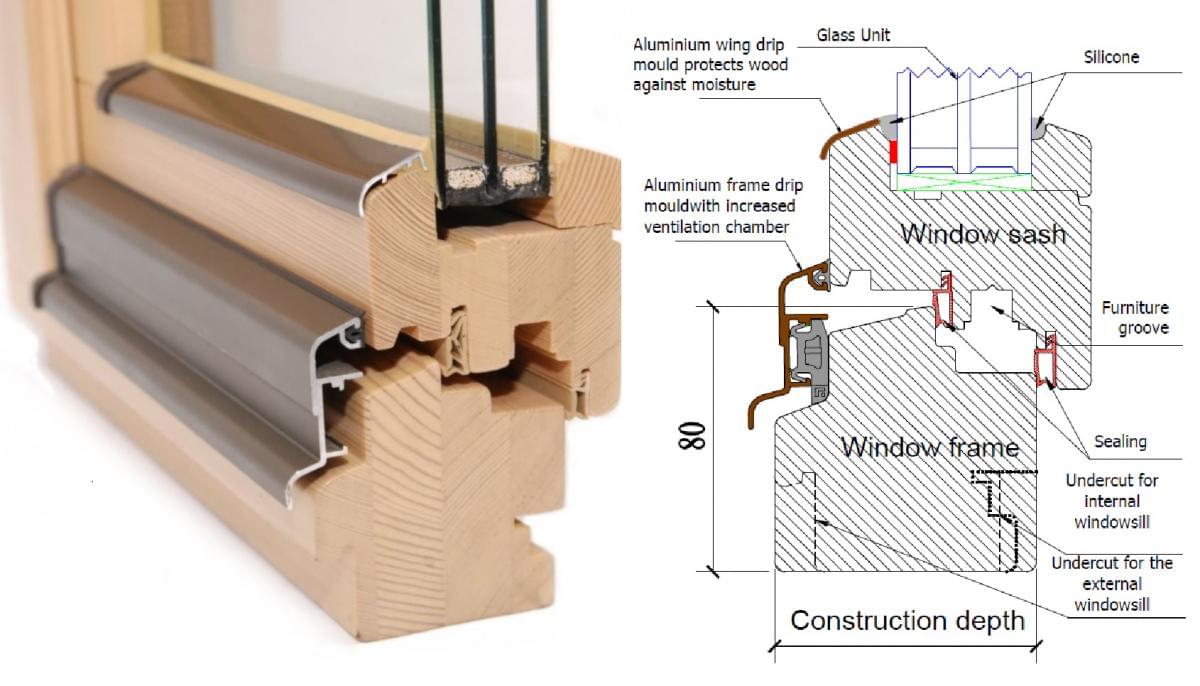

Wooden window frame and sash

Wooden window frame and sash are made from laminated wooden scantlings consisting of multiple layers glued in thickness (lamellae). The middle lamellae of the scantling are usually finger-jointed, the external can be both jointed (the so-called “glued” or optimized scantlings) and solid unjointed (fixed scantlings). Windows are most commonly made from pine or oak scantlings; however, material of other wood species is also available, for instance, larch, meranti, sipo etc.

The width of frame and sash profiles is usually 80mm, thickness 68, 78, 90 or 98mm. Windows opening inwards. The bottom of the frame contains cuts for easy installation of internal and external windowsills.

For finishing of windows and other structures, we apply the water-based impregnant, primer, paints and varnishes produced by Teknos. We offer 54 tones of tinted varnish and covering paints according to RAL or NCS catalogues.

Thermal conductivity coefficient of a window

Thermal conductivity coefficient of a window Uw represents the heat loss through a square meter of the window area when the temperature difference is 1°C. The lower the number, the more energy-efficient is the window (saving heat). According to the standard DIN EN ISO 10077-1, it is calculated and also verified for turn-only windows with dimensions 1230*1480mm. Uw is mainly determined by thermal conductivity of the insulating glass unit and wooden frame and sash, as well as by the spacers of the insulating glass unit and sash seals. By choosing an insulating glass unit with the so-called “warm” spacer, Uw of the window may be reduced by approximately 0.1 W/m2*K. Since usually the thermal conductivity of an insulating glass unit is significantly lower than that of the wooden frame and sash, then Uw will be higher for a smaller window and window with divisions. This means that heat losses through a square meter of the window will increase. For wooden windows, Uw ranges from 0.7 to 1.8 W/m2*K depending on the profile system, the type, size and configuration of the insulating glass unit.

Insulating glass unit

An insulating glass unit consists of 2 (a single-chamber unit) or 3 (a double-chamber unit) glasses and separating slats or spacers, the whole structure is glued and sealed using a butyl sealant. Spacers usually are made of aluminium or aluminium combined with plastic materials (the so-called “warm” spacers). The space between the glasses is filled with argon. Energy-efficient insulating glass units feature a special (selective) coating on the glass surface, which reflects the infrared (heat) radiation back into the room reducing heat loss. This feature of the insulating glass unit is characterized by thermal permeability coefficient Ug (W/m2*K). The smaller the coefficient, the less heat is lost through the insulating glass unit. For a single-chamber insulating glass unit (with 2 glasses) the Ug value is around 1.1 W/m2*K, for a double-chamber (with 3 glasses) it ranges from 0.8 up to 0.5 W/m2*K, depending on the glass type, the type of selective coating and thickness of the insulating glass unit. For comparison – for a 4mm single-layer glazing Ug =5.7 W/m2*K.

The sound insulation

The range of human ear sensitivity is extremely wide, therefore in acoustics the sound intensity is measured in logarithmic units – decibels (dB). The quietest sound a human ear can perceive (threshold of hearing) is assumed to be 0 dB. Different volume levels can be roughly described as follows:

20 dB- rustling leaves (100 times greater sound intensity than 0dB)

30 dB- whisper (1000 times greater sound intensity than 0dB)

40 dB- peaceful classroom (10000 times greater sound intensity than 0dB)

50 dB- a passing car (100000 times greater sound intensity than 0dB)

60 dB- human speech (1000000 times greater sound intensity than 0dB)

80 dB- heavy traffic in city

100 dB- perforator

120 dB- rock concert

140 dB- pain threshold (100000000000000 times greater sound intensity than 0dB)

180 dB- rocket launch

Therefore, if the sound insulation of a window is 30 dB, which means loss of sound intensity by 1000 times, the human voice speaking outside the window we hear as a whisper. The change in volume by 3 dB people perceive as barely noticeable.